BROCHURE

Contact YPT for a detailed information about YPT Carbon Regeneration Kilns.

YPT Quality Management System

For detailed information about YPT Quality Management System

YPT Process Equipment Factory

For detailed information about YPT Process Equipment Factory

Restoring Carbon Activity for Continuous Gold Recovery

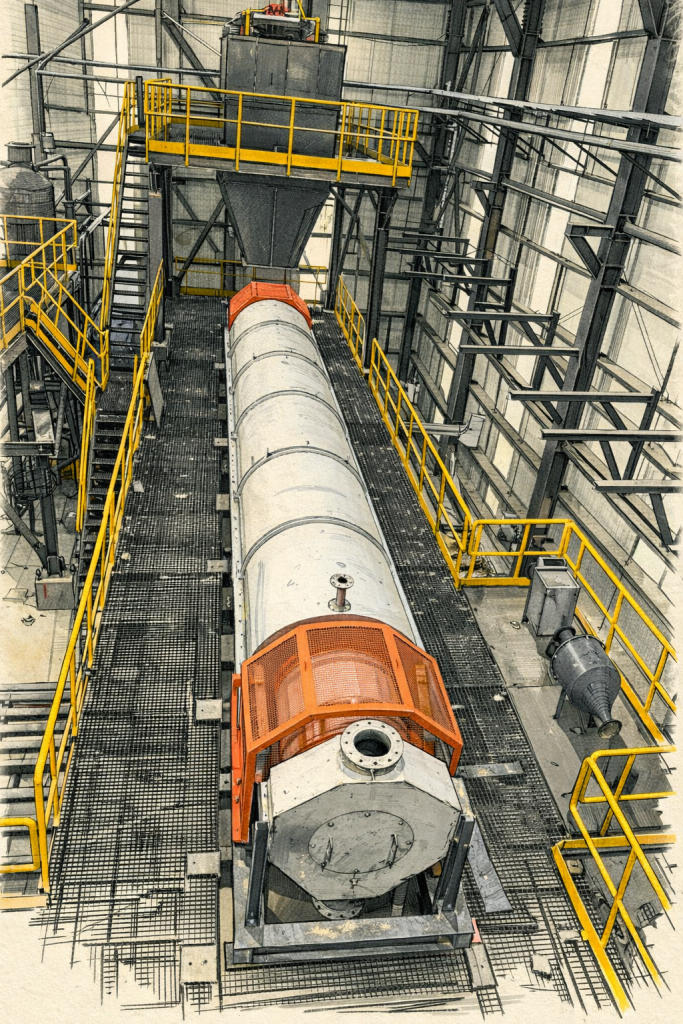

YPT Carbon Regeneration Kilns

A Carbon Regeneration Kiln is a specialized thermal system designed to restore spent activated carbon to its original adsorption capacity.

In mineral processing (especially gold processing circuits employing the carbon-in-pulp (CIP) or carbon-in-leach (CIL) methods), activated carbon adsorbs dissolved gold (and other metals) from cyanide solutions.

Over time the carbon becomes “fouled” by organic and inorganic contaminants which reduce its activity (its ability to adsorb).

The regeneration kiln heats the spent carbon in a controlled environment—often under steam, inert gas or low-oxygen conditions—to remove or decompose the foulants, thereby re-activating the carbon and enabling reuse.

In mineral processing (especially gold processing circuits employing the carbon-in-pulp (CIP) or carbon-in-leach (CIL) methods), activated carbon adsorbs dissolved gold (and other metals) from cyanide solutions.

Over time the carbon becomes “fouled” by organic and inorganic contaminants which reduce its activity (its ability to adsorb).

The regeneration kiln heats the spent carbon in a controlled environment—often under steam, inert gas or low-oxygen conditions—to remove or decompose the foulants, thereby re-activating the carbon and enabling reuse.

Proven Kiln Technology for Active Carbon Regeneration

YPT Carbon Regeneration Kilns Highlights

Thermal Efficiency Meets Metallurgical Precision

Design Criteria

Carbon throughput: | Tonnes per day of spent carbon to be treated. This sets the kiln size, drum length/diameter or vertical kiln dimensions. |

Temperature and atmosphere: | The kiln must achieve sufficient temperature to remove foulants without damaging the carbon structure. Steam or inert atmospheres are frequently used to control oxidation. |

Residence time: | The duration the carbon remains within the high-temperature zone is critical to allow desorption of contaminants. Design must allow sufficient time for regeneration. |

Carbon attrition and physical degradation: | The regeneration process can cause carbon particle degradation (fines generation) which leads to loss of carbon and possibly gold loss. Kiln design should minimise mechanical stress and attrition. |

Heat recovery and energy efficiency: | Because high temperatures are involved, design often includes heat-recovery (e.g., recycle ducts, steam generation) to reduce fuel/energy consumption. |

Emission control and environmental compliance: | Volatilised contaminants and gaseous emissions must be treated via after-burners or scrubbers. The kiln atmosphere and discharge must meet emissions standards. |

Material construction and wear: | The kiln components (drum, liners, seals) must tolerate high temperatures, corrosive/abrading carbon, steam, and inert gas cycling. Design must allow access for maintenance and pre-empt wear. |

Technical Specifications

Operating | ~650-850 °C | Depends on foulant load and carbon type. |

Carbon | ~0.5 to ~20 t/day (or higher for custom units) | |

Carbon | ~5-10% per regeneration cycle | |

Steam injection | Required to avoid carbon combustion | |

Heat | Often included to reduce fuel consumption | Energy-efficiency measure. |