BROCHURE

Contact YPT for a detailed information about YPT Conveyor Belts.

YPT Quality Management System

For detailed information about YPT Quality Management System

YPT Process Equipment Factory

For detailed information about YPT Process Equipment Factory

Moving Your Material, Sustaining Your Momentum

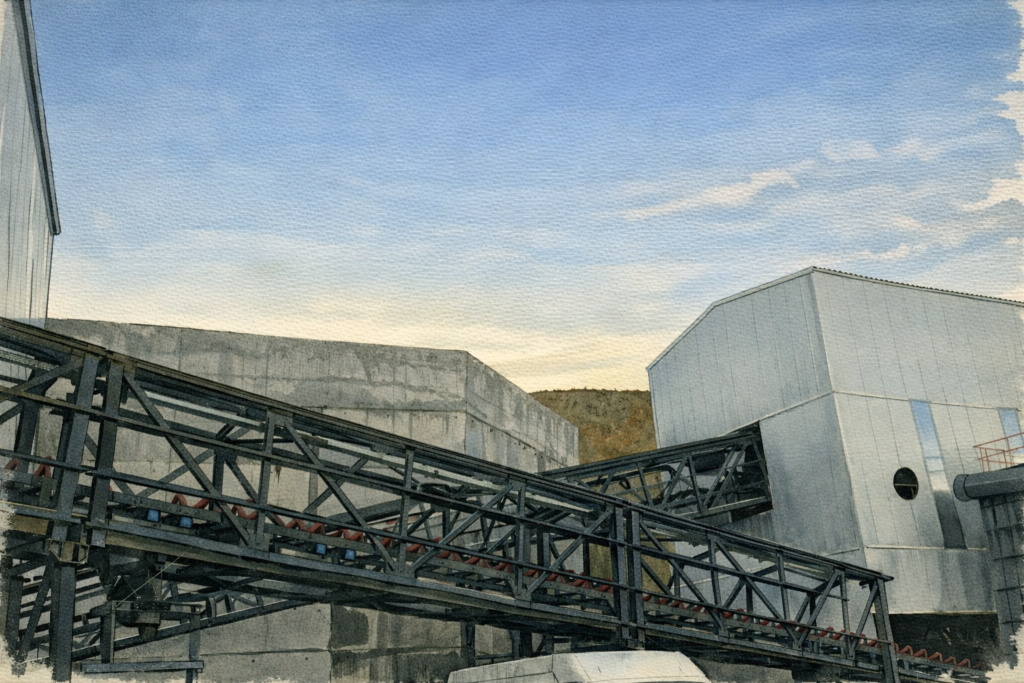

YPT Conveyor Belts

A conveyor belt is a continuous loop of material (typically rubber, fabric, steel-cord reinforced) driven by pulleys that transports bulk material from one point to another.

In mineral processing, belt conveyors form the backbone of material movement — from ore feed to crushers, mills to classifiers, tailings transport and stockpile reclaim.

The basic principle is simple: a carrying pulley, a return pulley, the belt loop, and idlers/rollers to support load and return.

In mineral processing, belt conveyors form the backbone of material movement — from ore feed to crushers, mills to classifiers, tailings transport and stockpile reclaim.

The basic principle is simple: a carrying pulley, a return pulley, the belt loop, and idlers/rollers to support load and return.

Reliable Conveying for Demanding Mining Operations

YPT Conveyor Belts Highlights

Engineered Flow. Continuous Performance

Design Criteria

Material characteristics: | Lump or particle size, bulk density, moisture/slurry content, abrasiveness, angle of repose and surcharge. These influence belt width, trough angle, idler spacing, skirtboard width. |

Capacity | Determines belt speed × cross-sectional loading determines width. |

Belt width, | From design guides: wider belt means lower speed for same capacity, reducing wear and spillage; troughing sets (typically 35°, 45° rollers) help maintain load. |

Belt construction: | Top cover (abrasion resistance), carcass (tensile strength, elongation), bottom cover (wear from rollers). For mining: fabric carcasses or steel-cord belts for long distances or high tension. |

Speed limitation: | High belt speeds increase wear, dust, spillage. As per “Ten common mistakes” article: substituting speed for width is a frequent error. |

Skirtboard width | To prevent spillage in loading zone, as per CEMA guidance ~⅔ belt width for skirtboard in many bulk handling conveyors. |

Tensioning and | Proper take-up arrangement (screw, counterweight, hydraulic) required to maintain belt tension, prevent slippage, and ensure long service life. |

Idler/trough | Proper spacing of idlers, troughing sets, return sets, impact bars at loading zones. Ensure belt tracking and minimize belt sag. |

Pulley design: | Pulley diameter relative to belt thickness for metal belt conveyors, ratio ≥ 625:1 to maximize belt life. |

Straight vs incline | Depending on path and elevation changes. |

Standards: | Design codes such as IS 11592:2000 (India) give guidance for belts 300-2000 mm width, referencing ISO 5048 for belt conveyor calculations. |

Technical Specifications

Belt | 500 mm – 3000 mm+ | Based on capacity, lump size |

Belt | ≈1.5 – 6 m/s (bulk) | Higher speeds increase dust/spillage risk |

Top cover thickness | 3 mm – 10 mm+ | Depends on abrasiveness |

Carcass tensile strength | Fabric: e.g., 200–1000 N/mm; Steel-cord: up to 5000 N/mm | For long distances/high tension |

Drive | Varies widely | Depends on load, length, elevation change |

Idler | Carry: ~1–2 m; Return: ~2–4 m | Depends on belt width/weight |

Maximum incline angle | 18°–23° in bulk duty; steeper use cleated/pipe belts | Material and lubrication dependent |