BROCHURE

Contact YPT for a detailed information about YPT Electrowinning Cells.

YPT Quality Management System

For detailed information about YPT Quality Management System

YPT Process Equipment Factory

For detailed information about YPT Process Equipment Factory

Transforming Ion to Metal Through Controlled Electrowinning

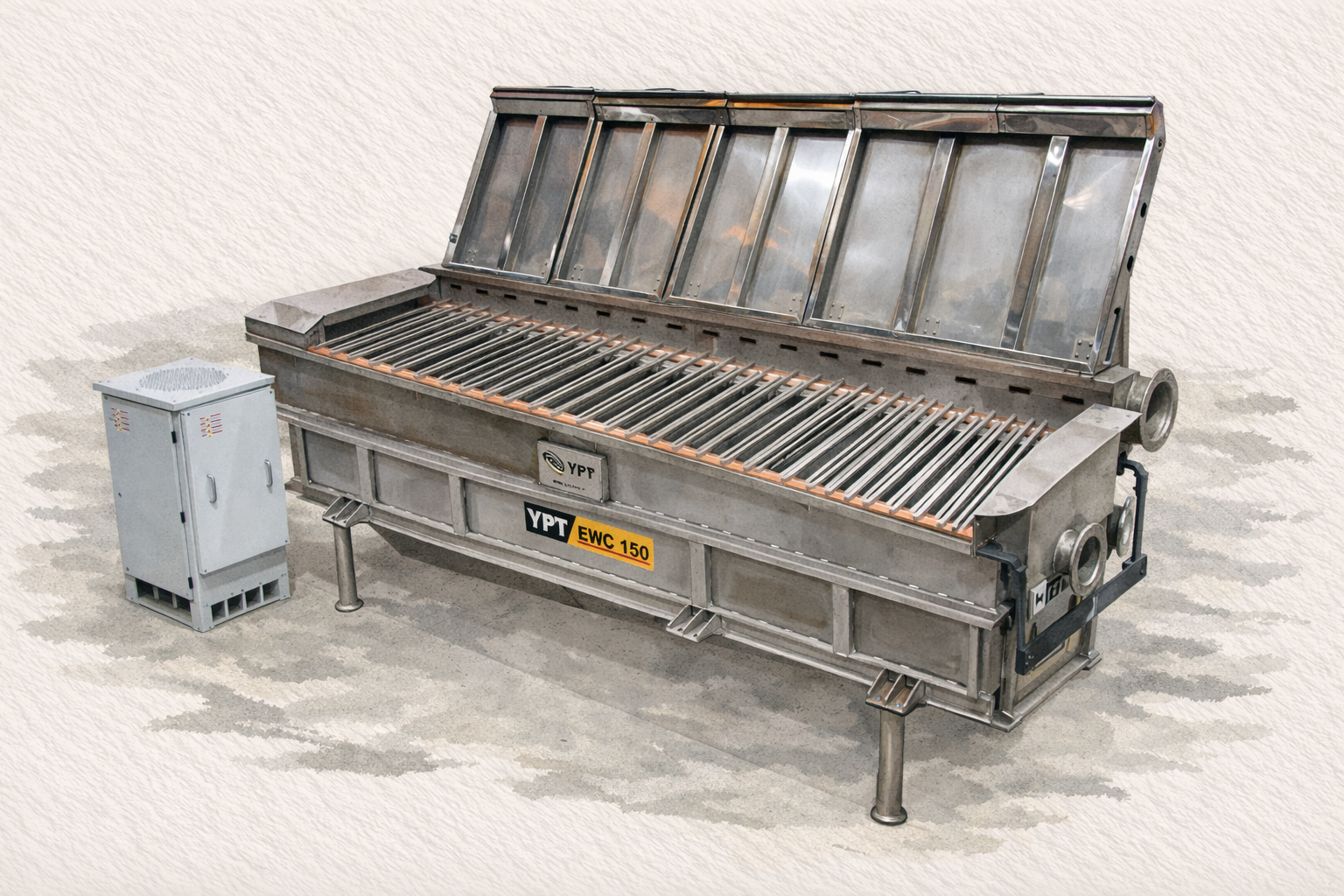

YPT Electrowinning Cells

An electrowinning cell is an electrolytic device used in hydrometallurgical processes to recover metal from solution by depositing it onto cathodes under the action of an applied current.

In the context of precious-metal recovery (e.g., gold, silver), or base metals (copper, zinc), solution from leaching/elution circuits is passed through a tank containing cathodes and anodes; metal ions migrate and are reduced on the cathode surface, forming a metal deposit that is later removed.

Electrowinning cells are key units in circuits such as 'SX-EW' (solvent extraction – electrowinning) for copper recovery, or in elution/precious metal recovery loops.

In the context of precious-metal recovery (e.g., gold, silver), or base metals (copper, zinc), solution from leaching/elution circuits is passed through a tank containing cathodes and anodes; metal ions migrate and are reduced on the cathode surface, forming a metal deposit that is later removed.

Electrowinning cells are key units in circuits such as 'SX-EW' (solvent extraction – electrowinning) for copper recovery, or in elution/precious metal recovery loops.

Efficient Metal Recovery with Proven EW Design

YPT Apron Feeder Highlights

Precision Current... Pure Metal...

Design Criteria

Cathode active area: | The area available for metal deposition is critical; for a given production rate, increasing cathode area reduces current density and may improve deposit quality. |

Current density and current efficiency: | High current densities increase production rate per area but may reduce current efficiency (because of side reactions, increased over-voltage). The current efficiency is the fraction of current that is effectively used for metal deposition rather than side reactions. |

Electrolyte flow and mixing: | Ensures uniform concentration of metal ions, removal of hydrogen bubbles or gas at cathode surface, and reduction of resistive losses. Poor flow may lead to uneven deposition or early termination of the cycle. |

Cell voltage and power supply (rectifier): | The voltage is determined by the sum of electrical resistances (electrolyte resistance, electrode resistance, contact resistance) plus the decomposition potentials of reactions. Typical cell voltages in electrowinning may range from ~1.8 V to 2.5 V in certain copper EW circuits. |

Material of electrodes: | Cathodes often steel-wool or steel mesh (for precious metals) or stainless steel cathode sheets; anodes may be stainless steel, lead alloys or other inert materials depending on chemistry. Electrode life, corrosion resistance, ease of stripping must be considered. |

Cell size, layout and scalability: | Number of cells (in series or parallel) determines total cathode area, throughput, and voltage distribution. Cells must be designed for easy maintenance, sludge/metal removal, and service access. |

Impurity control: | Presence of iron, sulphates, cyanide, other metals or gangue can reduce efficiency, plate quality, cause short-circuiting or increase maintenance. For example, iron in copper EW increases undesirable side reaction reducing current efficiency. |

Footprint and infrastructure: | Cells require space, power supply (rectifier), electrolyte circulation pump(s), feed and discharge piping, and often ventilation (especially for hazardous solvents or gases). In precious-metal cells, fumes capture (e.g., cyanide fumes) may be necessary. |

Technical Specifications

Cell | ~1.8 V – 3.0 V | Depends on chemistry, electrode spacing, solution conductivity |

Current | ~100 - 1000 A/m² (varies widely) | Precious metals may use lower density for quality; base metals higher density |

Cathode area | ~5 m²-20 m² (depending on design) | Scalable for plant size |

Deposition | kg metal per hour per cell area – depends on current, efficiency and metal tenor | Based on Faraday’s law |

Electrolyte | ~2000-5000 µS/cm (or higher) | Higher conductivity reduces resistance and voltage losses |

Electrolyte | Designed to maintain turbulence and refresh boundary layer at cathode surface | Critical for efficient deposition |

Cell | rectangular box ~1 m wide × 1.5-2 m deep × 5-7 m long (for copper EW) |