BROCHURE

Contact YPT for a detailed information about YPT Wobbler Feeders.

YPT Quality Management System

For detailed information about YPT Quality Management System

YPT Process Equipment Factory

For detailed information about YPT Process Equipment Factory

Built for Tough Materials

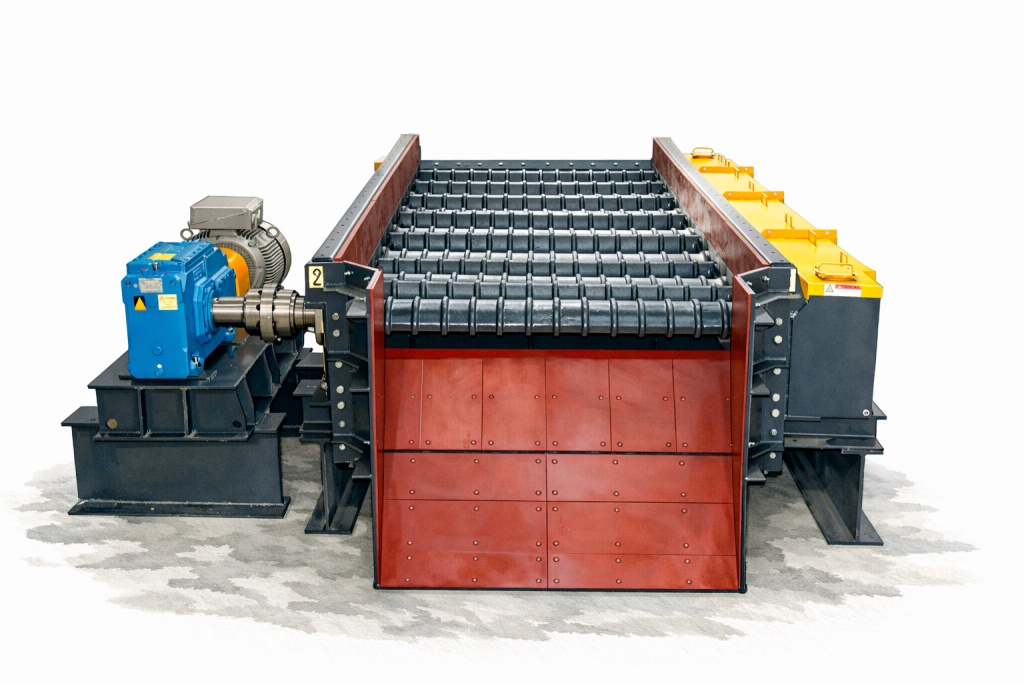

WBL Series Wobbler Feeders

A Wobbler Feeder is a specialised piece of bulk-material processing equipment that combines feeding and pre‐screening (scalping) functions, particularly designed to handle wet, sticky, clay‐bound or fine-laden feed material that tends to clog conventional feeders or vibrating grizzly screens.

The device consists of a series of rotating shafts on which elliptical or triangular bars (sometimes called “wobbler bars”) are mounted in parallel. These bars rotate in unison but with phased offsets, producing a “wobbling” or tumbling action that agitates the material, separates fines and clay/sludge, and ensures a uniform feed of the coarse or desired material into the downstream crusher or conveyor.

In short, the wobbler feeder acts as a robust “self-cleaning” feeder/scalper combination, enabling downstream plant throughput, reducing blockages and improving feeding consistency in challenging feed conditions.

The device consists of a series of rotating shafts on which elliptical or triangular bars (sometimes called “wobbler bars”) are mounted in parallel. These bars rotate in unison but with phased offsets, producing a “wobbling” or tumbling action that agitates the material, separates fines and clay/sludge, and ensures a uniform feed of the coarse or desired material into the downstream crusher or conveyor.

In short, the wobbler feeder acts as a robust “self-cleaning” feeder/scalper combination, enabling downstream plant throughput, reducing blockages and improving feeding consistency in challenging feed conditions.

Areas of Application

Wobbler feeders are used in a variety of mineral processing, aggregate and bulk-materials operations. Key application areas include:

By integrating the feeding and scalping functions, the wobbler feeder helps improve plant efficiency, reduce crusher wear (by removing fines/clays), lower maintenance and manage difficult feed materials.

Heavy-Duty Feeding for the Toughest Conditions

YPT Wobbler Feeder Highlights

Continuous, Clog-Free Feeding for Uninterrupted Flow

Design Criteria

Material characteristics: | lump size, bulk density, moisture content, clay/silt content, abrasiveness. Higher moisture or fine clay content increases the need for wobbler action. |

Feed rate / tonnage: | The required throughput drives the width, deck length, number of shafts, bar pattern and drive power. |

Deck length and width: | Longer decks allow more time for tumbling/separation of fines; width determines the capacity and allows accommodation of large lumps. |

Bar geometry and shaft offsets: | The elliptical/triangular bars and phased shaft arrangement determine the “throw” and tumbling effect. Proper gap size between bars is key to unwanted fines passing through. |

Inclination / angle of deck: | Some wobbler feeders have slight incline to aid flow; design must account for material behavior on the deck. |

Robust construction: | High-impact loads (large lumps, loading trucks, blockages) require heavy structure, wear liners, strong bearings and often oversized drives. |

Maintenance access / reliable drives: | Because the units are used in demanding conditions, design should consider ease of inspection, lubrication, replacement of bars, and robust drive systems (gearbox, coupling) with overload protection. |

Integration with upstream/downstream equipment: | The wobbler feeder should be matched to the feed source (bin, dump, truck) and the downstream crusher/conveyor, including feed profile, distribution and uniformity. Pre-screening of fines helps protect crusher efficiency and reduce wear. |

Technical Specifications

Deck width | ~1 000 – 2 400 mm | Based on capacity and lump size |

Deck length | ~3 000 – 9 000 mm | Longer deck = more separation time |

Capacity (tonnes/h) | ~200 – 1 000 t/h+ | Depends on width, length, material density |

Drive power | ~22 – 75 kW or more | Depending on size and load |

Bar spacing / gap size | ~30 – 150 mm | Determines minimum size passing through deck with correct design and power |

Shaft speed / bar speed | Synchronous drive, moderate RPM | Tumbling motion criticalon load, friction and speed |

Wear materials / liners | Hardened steel, manganese, wear plates | Important given heavy duty dutyand lubrication dependent |

Inclination angle | Horizontal to slight incline | Often near horizontal for separation standard |